Vibro Shifter in Hyderabad

A Vibro Shifter (also known as a Vibro Sifter or Vibrating Sieve Machine) is a mechanical device used for separating, grading, or sieving bulk materials in various industries. It uses vibratory motion to screen materials and separate them based on particle size, ensuring that only particles of the desired size pass through while larger or unwanted particles are filtered out.

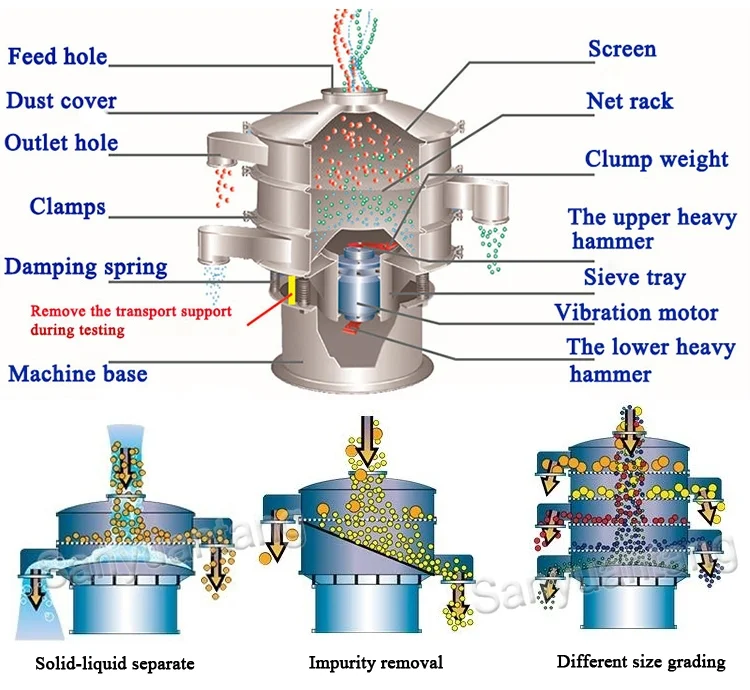

The Vibro Shifter operates on the principle of vibratory motion. A vibrating motor (or several motors) generates a rapid circular or linear movement that causes the material to move across the surface of the sieve. The vibration accelerates the movement of particles, helping them pass through the mesh if they are small enough, while larger particles remain on top for further processing or disposal.

Vibro Shifter Manufacture in Hyderabad

- Vibrating Motor: The primary component responsible for creating the vibratory motion. It generates the vibrations required for material screening.

- Sieve/Screener: A mesh or perforated plate that acts as a filter to separate particles based on size. Multiple sieve layers can be used for multi-grade separation.

- Spring/Isolators: These absorb the vibrations generated by the motor and prevent them from transmitting to the rest of the structure.

- Base Frame: The support structure that holds the entire system in place.

- Inlet and Outlet: Where materials are fed into and discharged from the Vibro Shifter.

- Pharmaceutical Industry: To ensure uniform particle size in powders and granules used in drug formulations.

- Food Industry: For grading flour, sugar, spices, and other powdered or granular ingredients.

- Chemical Industry: For sieving chemicals, pigments, and powders to ensure quality control.

- Cosmetics Industry: For filtering and grading cosmetic powders or liquids.

- Agriculture: For sieving grains, seeds, and fertilizers.

- Mining and Metallurgy: Used to separate ores, minerals, and other materials based on particle size.

- Efficient Screening: Can screen materials quickly and efficiently with high precision.

- Hygienic Operation: Designed for easy cleaning and maintenance, especially for food and pharmaceutical applications.

- Adjustable Speed: The vibration intensity can often be adjusted to match the material’s characteristics.

- Multi-Grade Separation: Can separate materials into multiple grades or sizes with a single pass through the machine.

- Compact Design: Occupies less space compared to other screening machines.